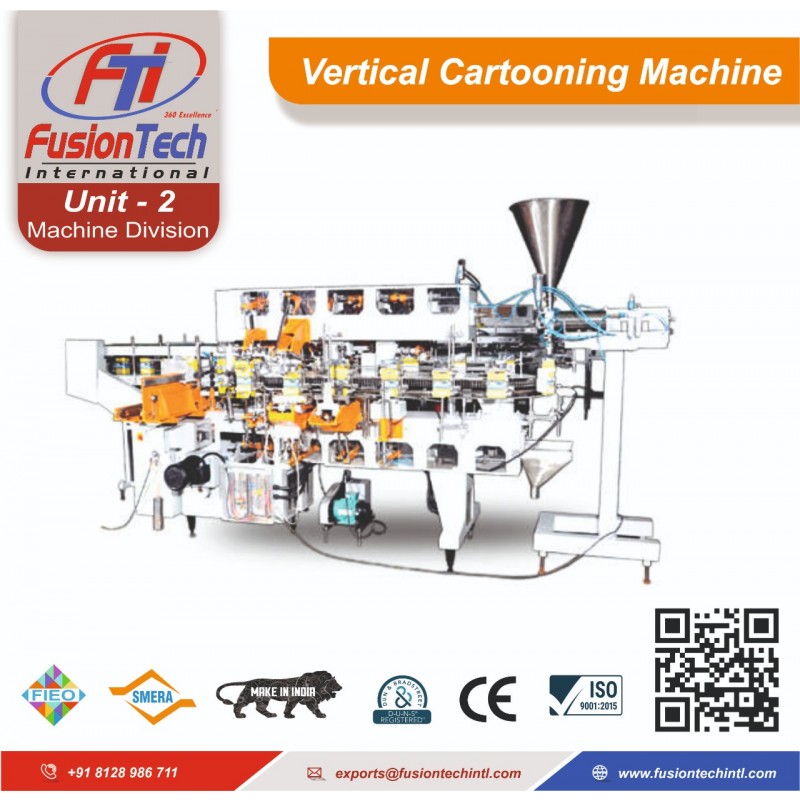

TECHINICAL DETAIL OF Automatic Cartooning Machine - VERTICAL - Tucking Mechanism - Max 120 Ppm INPUT SPEED : 80~120 MPM (AVERAGE SPEED CONSIDERED)

CARTON DIMESIONS RANGE: WIDTH: 25~100 MM | HEIGHT: 15~100 MM | LENGTH: 60~250 MM MAGAZINE CAPABILITY: 500~800 CARTONS.

MECHANISM: MANUAL FEEDING AUTOMATIC CARTONING - Link Possible Depending On Layout - May Charge Extra.

APPLICATION: DROP AND PLACE IN CARTOON.

DISCHARGE: VERTICAL DROP

PRINCIPAL OF OPERATION

> End Load Carton Is Removed From A Supply Magazine Via A Reciprocating Vacuum System

> Carton Is Erected And Placed Down On Continuous Moving Chain System

> The Product Will Be Manually Loaded Into Carton, . Please Note, Products Can Be Comfortably Loaded In The Open Carton Depending On The Clearance Given.

> Loaded Carton Is Then Transported Through The Machine And Is Glued / Tucked And Closed.

> Completed Cartons Are Then Automatically Delivered From The Front Of The Machine At A Convenient Working Height

> Synchronized With Hot Melt Glue Closing System If Required.

> Provision For INK JET Printing Integration With The Machine (EXTRA & OPTIONAL).- Ink Jet Printer -Customer's Scope Of Supply

> Provision For Making It Online (infeed) For Continuous Motion (EXTRA & OPTIONAL) - Automatic Infeed Mechanism - Can Be Link - If Conveyor Required As Per Layout - That Will Be Considered As Extra At Actual

Manpower:

One Technically Trained Operator To Operate The Machine & 1 Unskilled Person. All Standard & Reputed Bought Out Components, Like Motor, Vacuum Pump, Gearbox, VFD & Pneumatic Components.

Safety: SS Guards & Interlock Will Be Provided Wherever Necessary To Prevent Any Injury To The Person Working On The Machine.

Features

- Continuous Motion Variable Speed

- Up To 120 Cartons Per Minute ( Depend On Product & Carton Size)

- Accommodates Glue Sealing Option Or Tuck Style Closure

- Left Hand Load

- Straight Front Discharge

- All Electricals Of Reputed Brand Such As Delta, Allen Bradley Etc. Or As Requested.

- Machine Electronic Panel And Guards Will Be Made Of Stainless-Steel Material Only.

- Note: Machine Will Be Designed To Pack As Per Your Required Product & As Per Your Samples Only

(*Cartons Made Of Good Quality ITC Board , With Grain Direction Perpendicular To Length, Suitable Automatic Carton Packing Line.)

STANDARD FEATURES

- Product Pushing Device

- No Product No Carton.

- All Guards In SS Sheet 304.

- SS Panel Body And Separate Operating Panel.

- Separate Vacuum Pumps For Carton Pick-up.

Following Will Be The Make Of The Bought Out Components .

o VFD – Delta / Any Standard

o Gear Box – Bonfiglioli / MotoVario

o Pneumatics – Festo /SMC/Janatics

o Switch Gears – Siemens/Any Stndard

o Interlocks/ Sensors – Sick/ P & F/Any Standard

o PLC /HMI – Delta / Mitsuibishi / Any Standard

o Electrical & Operating Panel- MS Powder Coated.

o Fastners/ Pulleys/ V Belts Etc – Reputed Make.

Carton Dimensions Range. : Width: 25 – 100 Mm. Height: 15 – 100 Mm. Length: 60 – 250 Mm

Mechanical Speed: 100-120 Cycles/min.

Actual Output Of Packed Cartons: 80 Packs/min

Air Consumption: 40 L/min At 6 Kg/cm2 Pressure

Power Supply: 220V, AC, 50/60 Hz, 3Ph.

Power Consumption: 3 KW, TPH With Neutral & Earthing.

Machine Weight: Approx. 600kg. Gross Weight: Approx. 800kg.

Machine Dimension: 2500(W) X 2800(L) X 1800(H) Mm

Packing Case Dimension :2600(W) X 3000(L) X 2000(H) Mm (wooden Box - If Required)

Additional Points Considered For The Machine.

> Use Of Self Lubricating Bearings, Will Provide Points For Lubrication, Wherever Necessary.

> Sealing Of The Panel With Proper Rubber Lining To Avoid Ingress Of Dust.

> Additional Emergency Switches At Multiple Area Of The Machine To Easy Access In Case Of Emergency, Considering The Safety Aspects Of The Working Person On The Machine.

> Labeling On Panels & Machine In English.

> Powder Coating On All The Possible Fabricated Parts As Per Specified Shade.

> All Contact Parts Of The Product Will Be In SS Or Engineering Food Grade Plastic.

> All Fasteners Will Be Superior Quality With Chrome/Nickel Plated Unless Otherwise Specified

> Input Voltage Will Be 3 Ph + Neutral + Earthing.

> Safety Guards Will Be Provided As Per Industry Standards.

> Operation Manual Will Be Provided. SOP Will Be Made Jointly After The Machine Is Installed & Commissioned In The Factory.

> One Set Of Emergency Free Spares & Tool Box Will Be Provided.

> A List Of Recommended Spares For One Year Of Operation, With Make Of All The Bought Out Components Will Be Provided.

** In Case Of Hot Melt Glue System & Ink Jet Printer To Be Provided, The Same Should Be Extra At Actual Supplied To Us For Integration On The Cartooning Machine.

English

English Arabic

Arabic

German

German

French

French

Sanskrit

Sanskrit